- Have any questions?

- +98(21) 887 50 887

- info@yekanniroo.com

Masterpact M Retrofit Solutions

Protection Testing and Commissioning Services

February 20, 2017

High current air circuit breakers 800 to 6300A

Features

Nominal current: 800 to 6300A ACBreaking capacity from 40 to 150 kA rms

Voltage rating: up to 690 V

3 and 4-pole versions

Fixed or drawout versions

Types of trip units: STR08, STR18, STR28, STR38, STR38S, STR58.

Applications

The Masterpact M circuit breaker is used to protect and control low voltage distribution systems. It can be installed in main LV switchboards (incoming units, main and secondary outgoers).There are many Masterpact M retrofit solutions that we mention some of them as below:

Masterpact M to Schneider Electric Masterpact NW upgrade solutions

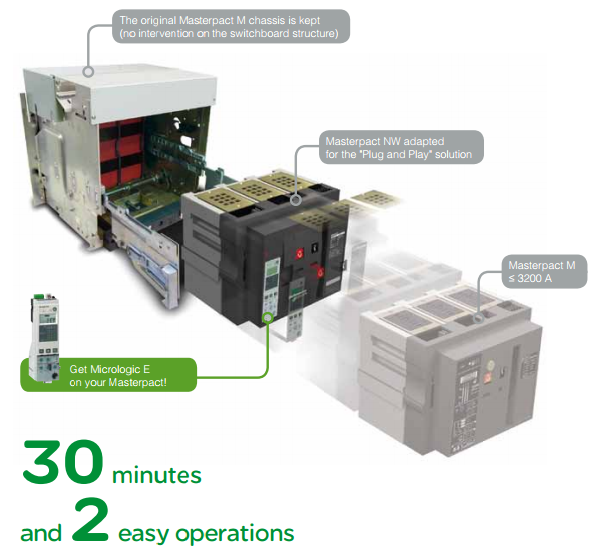

ECOFIT™ Plug & Play

The Plug & Play solution lets you retrofit the latest generation of Masterpact NW circuit breakers in the existing Masterpact M chassis. The standard Masterpact NW is adapted in the factory for installation in a Masterpact M chassis. More than just a replacement... ECOFIT™Plug & Play solution brings all the benefits of the Masterpact NW range, including the advanced features of Micrologic control units.

There are wide ranges equivalent functions of STR and Micrologic trip units:

STR-08, STR-18, STR-28, STR-38, STR-38S, STR-58 by micrologic 2.0A/E, micrologic 5.0A/E, micrologic 6.0A/E, micrologic 7.0A/E

A Plug & Play solution can only be implemented with Masterpact M chassis in full working order.However, spare parts are still available including:

disconnecting-contact clusters,

safety shutters,

auxiliary contacts.

30 minutes (typical time for simple installations) in 2 easy steps

The original Masterpact M chassis is first modified to receive the Plug & Play device.

The factory-adapted Plug & Play Masterpact NW is then installed in the modified Masterpact M chassis.

The on-site retrofit tasks are very simple

1.

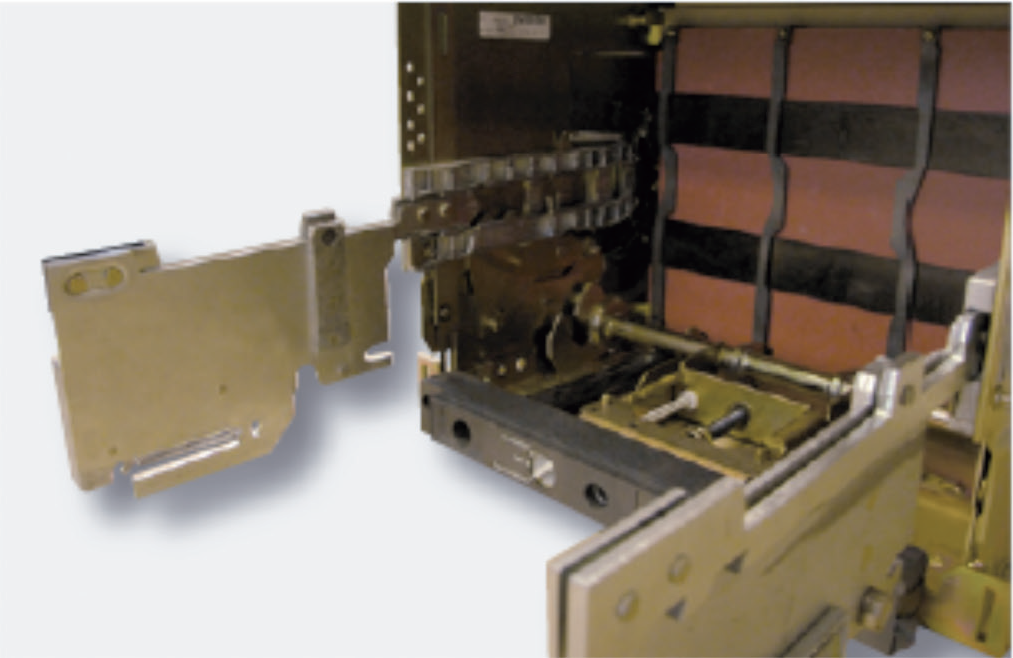

Replacement of the original drawer side plates Two new side plates are installed in place of the original plates on the Masterpact M chassis.

2.

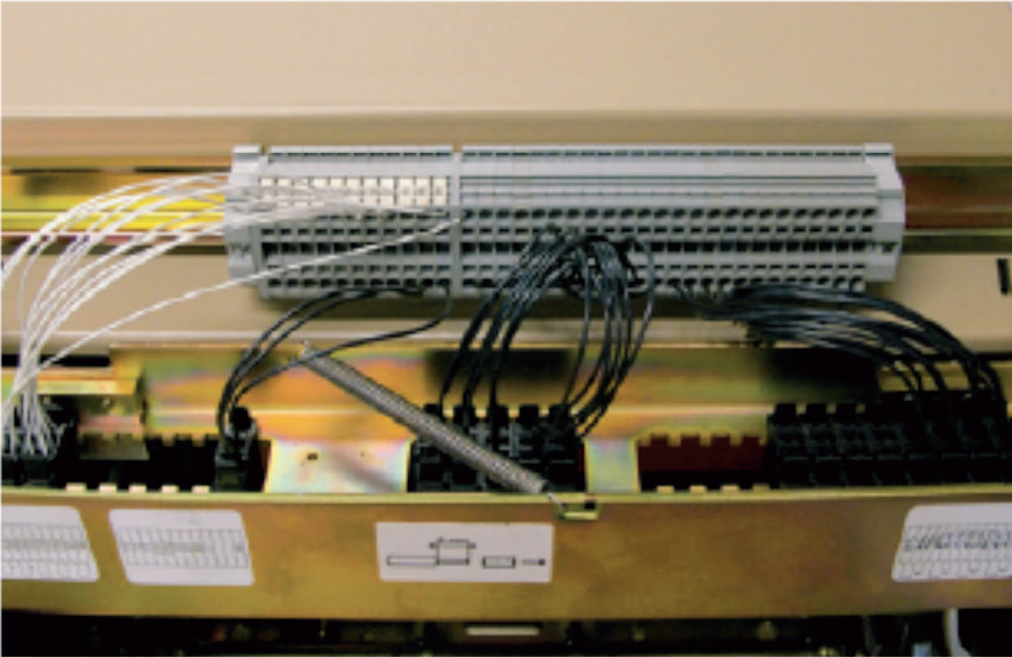

Replacement of the the auxiliary wiring connector plate All Masterpact NW functions are pre-wired. The required functions may be connected on-site using the supplied wiring instructions.The original escutcheon and cutout are used for the new device.

The only modifications required are the replacement of the drawer side plates and the auxiliary wiring connector plate.

These changes make it impossible to install a Masterpact M or standard Masterpact NW in the modified chassis.

The Plug & Play solution modernize Masterpact M circuit breakers with very short on-site servicing times. Shutdown of the entire installation is not required. Only the circuit supplied by the circuit breaker must be de-energised. This solution is particularly well suited to critical sites where the power supply cannot be interrupted for extended periods.

It is also ideal for switchboards installed in small rooms with no rear access, which is often the case for marine switchboards.

The combination of a Masterpact M chassis and a Masterpact NW circuit breaker has been factory tested, in particular for temperature rise and breaking capacity. For merchand marine applications and Bureau Veritas requirements, specific tests have been carried out under maritime conditions (humidity, vibrations, etc.).

ECOFIT™ Masterkit

ECOFIT™ Masterkit brings all the characteristics and functions of the Masterpact NW range, whatever the rating and performance level of the Masterpact M device.This solution is recommended for high performance levels to fully upgrade your installation. The ECOFIT™ Masterkit solution is designed to replace a Masterpact M circuit breaker by the latest Masterpact NW generation.

More than just a replacement…ECOFIT™ Masterkit solution brings all the benefits of the Masterpact NW range, including the advanced features of Micrologic control units.

Features

No modification of fixing points or connections required.No modification of the escutcheon or cutouts required.

Both solutions offer tested and validated connection systems to bring full performance in terms of breaking capacity and temperature rise.

ECOFIT™ Masterkit applications

Can be used for both fixed and drawout

devices with rear connections only.For fixed devices, the Masterpact NW comes with connections that enable to replace the former circuit breaker without modifying the busbars.

For drawout devices. The new chassis is equipped with special connections that replicate the connection points on the old Masterpact M chassis.

ECOFIT™ Masterkit solutions do not cover 1000 V and DC applications nor > M32 4P Neutral on right side. Consult France Grenoble ECOFIT Center.

ECOFIT™ Masterkit solutions are not suitable for Masterpact NW with corrosion protection.

ECOFIT™ Masterkit enables to benefit from all the enhanced features of Masterpact NW circuit breakers and accessories. It requires total shutdown of the installation to access the busbars.

Once upgraded, the switchboard is fully compatible with the Masterpact NW range, opening the door to circuit breaker interchangeability.

Installation down time is reduced because there is no need to modify the busbars. Performance is equal or better, depending on the busbar architecture.

Masterpact M to ABB SACE Emax 2 upgrade solutions

With only few modification actions and sustainable costs, Retrofitting kits are the perfect solution to extent life cycle of low voltage switchgear.

ABB ensures continuous operation between Masterpact M Air circuit-breakers and the newest series of circuit-breakers SACE Emax 2.

Replacement kits are designed to preserve existing switchgear performance specifications and reduce downtime to a minimum.

Special copper adapting kits can be mounted on SACE Emax 2 standard fixed part in order to replicate the copper bars connections of Schneider’s breakers. The result is a completely upgraded system with all the advantages of new technology offered by SACE Emax 2 circuit breakers.

Retrofitting kit consists of:

Dedicated plates for an easy installation of the circuit breaker;Special SACE Emax 2 adapter busbars according to the size to be mounted on the fixed part;

Adhesive template and metal adapters for panel door cutout;

Emax 2 fixed part.

Benefits

Tested solution that allows service continuity:Increased safety;

Easy installation;

Maintenance costs reduction;

Products and spare parts long availability;

Tested solution;

Wide range of mechanical and electrical accessories with Emax 2;

Power measurement with Emax 2 advanced trip units;

Programmed signal to remind to make maintenance;

Diagnosis and installation with Ekip Connect Software;

Ekip PowerController to improve energy efficiency and saving;

All Emax 2 accessories are compatible with the retrofitting kit (mechanical interlock and ATS are available only with Emax 2 circuit-breakers).